Nabholz Project Engineer Brandon Wall is currently working on the Arkansas Children’s Hospital Northwest project. On this project, Brandon used a variety of new construction technology to keep clients informed, check quality, and prepare solutions for possible issues. In this post, Brandon explains how each tool benefits our clients.

Inexpensive Solutions for Virtual Reality Experience

Do you remember playing with red plastic View-Master toys that opened up a 3D world of dinosaurs and travel when you were a kid? To create that whimsical effect, those toys used “stereoscopy,” a process that takes two images with slightly different offsets and then combines them in the same view to create a 3D image. This technology has developed since then, but Nabholz uses the same basic concept to produce an inexpensive, yet interactive, virtual reality experience for our clients. Using our suite of Autodesk products, we are able to generate stereoscopic renderings or stereo-panoramas from our BIM model and link them to a QR code, allowing these renderings to be viewed on a smart phone. Then, we use Google Cardboard, an inexpensive viewing device similar to the old View-Master, which uses these images on a smart phone to create an immersive view.

Do you remember playing with red plastic View-Master toys that opened up a 3D world of dinosaurs and travel when you were a kid? To create that whimsical effect, those toys used “stereoscopy,” a process that takes two images with slightly different offsets and then combines them in the same view to create a 3D image. This technology has developed since then, but Nabholz uses the same basic concept to produce an inexpensive, yet interactive, virtual reality experience for our clients. Using our suite of Autodesk products, we are able to generate stereoscopic renderings or stereo-panoramas from our BIM model and link them to a QR code, allowing these renderings to be viewed on a smart phone. Then, we use Google Cardboard, an inexpensive viewing device similar to the old View-Master, which uses these images on a smart phone to create an immersive view.

This service helps our clients visualize the finished project when the building is not far along in the construction process. In fact, on one hospital project walk through early on in construction, our owner requested an aide that would help visitors get a sense of the future project. Our owner was thrilled that on the walk through visitors could wear Google Cardboard, turn in a full circle, and see the space as if they were standing in the completed building.

Using Construction Technology/BIM to Avoid Rework in New Construction

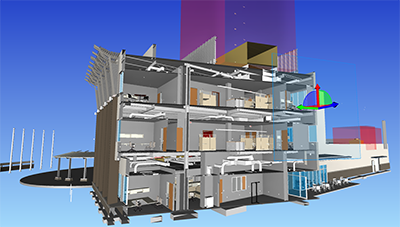

Nabholz projects often include highly complex mechanical, electrical, and plumbing systems. Things become even more complex when we integrate interior finishes around those systems. Additionally, in some instances it is much safer and less time-consuming to prefabricate ductwork, plumbing piping, or other overhead work before we start framing walls. These advantages make it well worth it to fabricate in advance, but when it’s time to install these prefabricated systems on site there is less flexibility for field-adjusted routing. That makes it crucial to get the coordination right on the front end, and BIM helps Nabholz do that.

One instance of re-work avoided through BIM was at a hospital project. The plumbing plans showed a large domestic water line running above the ceiling in a reception area, as planned. When we transposed the mechanical design into the 3D BIM model, we found that the called for elevation of the water line was designed too low and would have been exposed below the ceiling. Thanks to BIM, we were able to correct this problem. This simple fix highlights the real benefit of BIM—to solve the many seemingly simple issues revealed through the BIM model with a keystroke ahead of time.

One instance of re-work avoided through BIM was at a hospital project. The plumbing plans showed a large domestic water line running above the ceiling in a reception area, as planned. When we transposed the mechanical design into the 3D BIM model, we found that the called for elevation of the water line was designed too low and would have been exposed below the ceiling. Thanks to BIM, we were able to correct this problem. This simple fix highlights the real benefit of BIM—to solve the many seemingly simple issues revealed through the BIM model with a keystroke ahead of time.

360 Photos for In-Wall As-Built Documentation

Have you ever crossed your fingers when drilling into an existing wall in your house, maybe when mounting a shelf or hanging a picture, and worried about hitting a hidden pipe or electrical wire? On a commercial level, uncertainty of what lies beneath the gypsum board can equate to increased cost and time when trying to make light renovations or adjusting rooms. But how can you really know what’s inside your walls without removing sections of wall finish? We considered that question for our clients and came up with a solution—360 photos. We set up a special camera that takes a true 360-degree spherical image and host these images online for viewing from a smart phone or computer. We take the photos right before walls are sheathed. We can now give our clients’ maintenance staff a snapshot of the as-built in-wall conditions of every wall and ceiling in a single photograph. We link the photos to the project using a QR code in BIM 360 Field, which maintains the photos in a central location for future reference.

High-flying Drones for Jobsite Documentation

In recent years, drones have made in-roads in construction because of the advances in GPS tracking, camera technology, and ease-of-control. Nabholz ensures its drone pilots have the FAA-required license and comply with all regulations for use. We use drones to create a topographic survey of a project site, which we can use to perform cut/fill estimates and plan site logistics prior to any site remediation. We also use drones to take aerial progress photography and videography. We can now have those images in a matter of hours for a fraction of what a pilot and fixed-wing aircraft would cost.

In recent years, drones have made in-roads in construction because of the advances in GPS tracking, camera technology, and ease-of-control. Nabholz ensures its drone pilots have the FAA-required license and comply with all regulations for use. We use drones to create a topographic survey of a project site, which we can use to perform cut/fill estimates and plan site logistics prior to any site remediation. We also use drones to take aerial progress photography and videography. We can now have those images in a matter of hours for a fraction of what a pilot and fixed-wing aircraft would cost.

We’ve also used drones to inspect the exterior façade of the building and check for defects in exterior finishes. The uses and functionality of drones in construction continues to advance and we look forward to implementing this technology more widely on our projects.

Tablets for Increased Efficiency

We’re using tablets to replace expensive paper blueprints with the up-to-the-minute digital plans. In the video below, see how we’re using tablets on the Arkansas Children’s Hospital Northwest job.

At Nabholz, we don’t adopt new construction technology for the sake of newness, but rather when we know it will benefit our clients. We’re using these tools to look at your projects from new perspectives. Give us a call and we’ll share our view with you.