- Facilitate equipment maintenance and service

- Improve equipment reliability and longevity

- Provide safe and intuitive equipment operation

- Simplify the installation and equipment start up process

FEATURES & SPECIFICATIONS

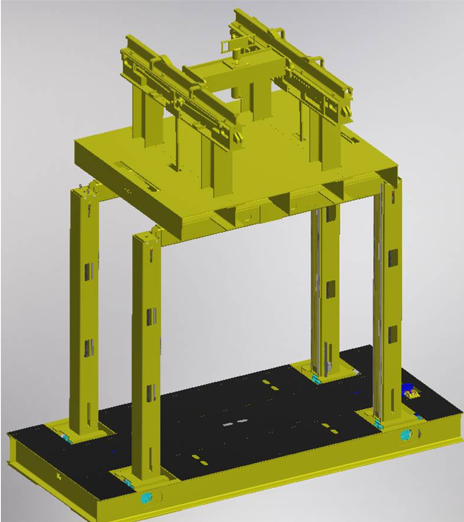

The jacking unit and crossbeams are designed so that the maximum lift height of the crossbeams extends above the crossbeams to minimize the pit depth required.

The base of the drop table carriage is covered with tread plate to protect electrical components and provide a safe walking surface when servicing the drop table.

A manual lock bar mechanism engages pockets in the foundation to support railcar and locomotive rollover.

Adjustable wheel chocks secure rail wheel at any location on the service top.

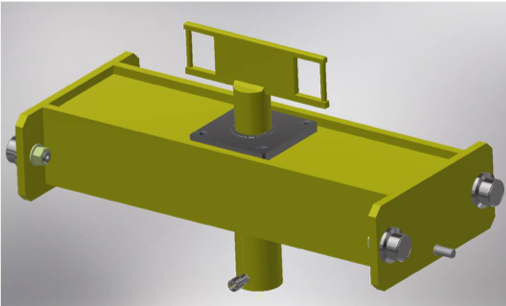

Rollers on the dolly allow it to be positioned along the rail, and locking pins on both sides hold it in place once positioned.

A jacking unit on the dolly allows the operator to adjust the height of the traction motor for proper alignment during the change out process.

Carriage traversing is guided by a double flanged wheel on one of the pit rails to prevent carriage misalignment caused by pit rails that are not straight.

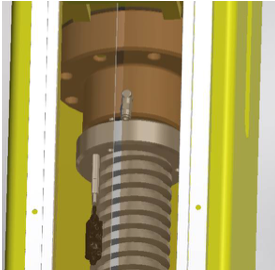

A steel safety nut is mounted under the bronze nut, and a nut wear switch incrementally monitors the wear of the bronze nut. This nut gap monitoring system is patent-pending. Grease is supplied to the screw and nut by a centralized automatic lubrication system.

*optional buttress threaded screw available

The front column opening is covered with high temperature nylon pads to protect the screw and nut from dust and debris.

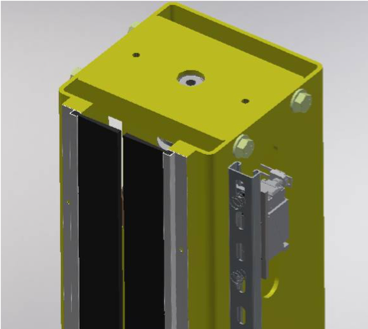

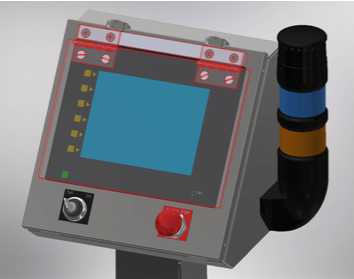

A hinged protective cover protects the touchscreen when not in use.

The control panel also includes an ON/OFF switch and an emergency stop switch, operation signal lights, and alarm.